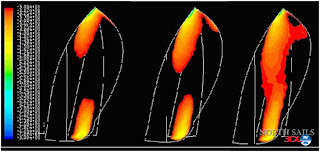

The images below display a sail development process utilizing the VWT to customize a sail shape. The original design on the left was altered based on the predicted flying shape from the pressure’s provided by the VWT and then analyzed with Membrain. The flying shapes and flow images are what allows the designer to know that he is producing a faster, more efficient shape. In this progression from left to right, an increase in efficiency of 2.3% more drive force was realized through this process. Maximizing the low pressure on the leeward side of the sail (more red & orange colors) is what we are after. You can see clearly, the increase represented below.

!!!...Wind tunnel testinG...!!!

Posted by

North 3dL SrI LanKa (Pvt) Ltd.

at

10:03 PM

North Sails has pioneered modern wind tunnel research for sails using two related-but-separate methods. The first is a traditional low-speed tunnel with a unique twist. The other is virtually amazing.

Twisted Flow Wind Tunnel

The University of Auckland's Twisted Flow Wind Tunnel (TFWT), developed in conjunction with North Sails, was created as a research tool to specifically simulate wind flow over yacht sails. It is the only commercial wind tunnel specifically designed for testing yacht sails. Using unique twisting vanes, the wind tunnel accurately models the gradient wind structure seen by a yacht moving through the water. The Twisted Flow Wind Tunnel has been used extensively by America’s Cup boats, Volvo Ocean Racers, Open 60s teams and other successful racing and cruising projects for over 10 years.

Virtual Wind Tunnel

The Virtual Wind Tunnel is the first (and still the only) computer simulator to accurately model wind flow on downwind sails at 100% scale. When first developed, North Sails used both the University of Auckland's Twisted Flow Wind Tunnel and BMW/Oracle’s ACC) to verify its accuracy. These comparisons and real-world performance have given us confidence that the “VWT” predicts results with more accuracy than typically encountered with wind tunnel sail testing of any kind. In addition to sail forces, the VWT provides insightful information to our designers relative to flying sail shape, sail drive, shape stability and ease of trim.

The images below display a sail development process utilizing the VWT to customize a sail shape. The original design on the left was altered based on the predicted flying shape from the pressure’s provided by the VWT and then analyzed with Membrain. The flying shapes and flow images are what allows the designer to know that he is producing a faster, more efficient shape. In this progression from left to right, an increase in efficiency of 2.3% more drive force was realized through this process. Maximizing the low pressure on the leeward side of the sail (more red & orange colors) is what we are after. You can see clearly, the increase represented below.

The images below display a sail development process utilizing the VWT to customize a sail shape. The original design on the left was altered based on the predicted flying shape from the pressure’s provided by the VWT and then analyzed with Membrain. The flying shapes and flow images are what allows the designer to know that he is producing a faster, more efficient shape. In this progression from left to right, an increase in efficiency of 2.3% more drive force was realized through this process. Maximizing the low pressure on the leeward side of the sail (more red & orange colors) is what we are after. You can see clearly, the increase represented below.

Subscribe to:

Post Comments (Atom)

0 comments:

Post a Comment